Three Major Advances in Micro LED Technology in 2018

Three Major Advances in Micro LED Display Technology in 2018

2018 is going to end, the development of Micro LED technology is undoubtedly the most eye-catching block of the LED Display Industry in 2018. Before we meet 2019, let us review the important moments of several Micro LEDs.

01/ KAIST Develops Vertical Flexible Micro LED to Promote Hair Growth

Recently, the Korea Institute of Science and Technology (KAIST) has developed a Micro LED wearable device that uses vertical Micro LEDs to successfully help mice re-grow their hair.

The device was tested on a back of a mouse that shaved hair using a flexible array of 900 vertical Micro LEDs. After 20 consecutive days of treatment, the hair growth of the mice was significantly faster than that of the untreated mice. Moreover, after treatment, the newly grown hair of the mouse is longer and the hair area is wider.

KAIST point out that, Micro LEDs do not heat up to the detriment of the human body and consume only one-thousandth of the energy per unit area compared to conventional phototherapy lasers. The research results can provide a new method for treating human hair loss.

02/ New Substrate Materials for Strengthening Micro LEDs Come Out

France's Soitec has invented a new substrate, InGaNOX, in the production of indium gallium nitride high-brightness blue LEDs, which can crystallize simultaneously on the substrate. Under the same substrate material, the three primary color Micro LEDs can be driven and controlled with the same voltage.

03/ New Innovation and Research Centers are also Bringing out Innovative Micro LED Solutions

The British company Optovate was founded in 2008 and has a long history of developing Micro/Mini LED technology. In March of this year, the company announced that it had made two breakthroughs in Micro LED. First, Optovate developed a esdled Micro LED Display stripping transfer technology that uses an ultraviolet laser and an adjustable pattern mask to lay the Micro LED chip off the substrate and directly onto the receiving substrate. Secondly, Optovate has also developed an optical array that combines the light emitted from the Micro LED chip with the principles of refraction and reflection. This technology can control micron-level chip light output for higher efficiency. When used for LCD and OLED panel backlights, Micro LED panels, etc., it can make the application design thinner.

The Belgian Microelectronics Research Center (IMEC) has also been actively involved in the development of Micro LED panel devices, focusing on the technology of rapidly transferring Micro LED chips to substrates. Through the development of the CSM machine spring structure, the Micro LED screen chip can be transferred to different substrates, and at the same time, the chip spacing can be adjusted to increase the transfer and assembly efficiency. Peter Lemmens, general manager of Imec Taiwan, believes that applications such as headsets or smart glasses will be expected to benefit first from the development of Micro LED Screen technology.

In addition, JBD in Hong Kong has also designed a heterogeneous integration technology that can realize monochrome red, green and blue Micro LED Display array module displays. JBD in On the March of this year, we have noticed that JBD uses wafer bonding (Wafer Bonding) to make Micro LED video wall wafer-level transfer (Wafer Level Transfer) to make a monochrome Micro LED module, especially Its green-light Micro LED array module has a brightness of up to 50K nits.

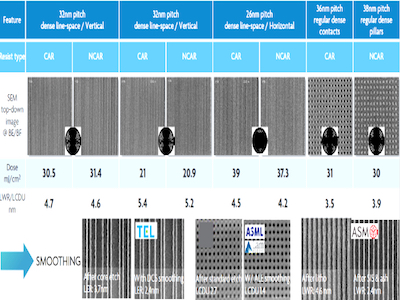

Micro LEDs have miniaturized chips and huge transfer characteristics, and require different levels of wafer production and processing processes. Therefore, the demand for equipment in the industry is more different than in the past. In order to continue the development of Micro LED commercial display technology, equipment manufacturers will also They have launched their own technology to strengthen the manufacturing of Micro LED.

Two major MOCVD manufacturers(led panel), AIXTRON and Veeco, have demonstrated the advantages of their devices in high-quality epitaxial silicon wafers with high wavelength uniformity and low defect density. Among them, Veeco and ALLOS Semiconductor formed an alliance to demonstrate the reproducibility of ALLOS 200 mm silicon gallium nitride epitaxial silicon wafer technology on Veeco Propel® MOCVD reactors in November.

AIXTRON does not give much to it. Its AIX G5+C and AIX 2800-G4 TM platforms offer MOCVD solutions and can achieve high-volume production targets. The GasFoilRotation® (GFR) Planetary Reactor® technology is a hybrid solution that combines single wafer rotation and batch reactor processing. Its satellite control uses GFR to achieve temperature control and flow regulation for a single wafer. AIXTRON's research and development of Micro LED technology also won the first prize of the Micro LED forward-looking technology competition.