Overview of Electron Paramagnetic Resonance (EPR) in the United Kingdom

Electron Paramagnetic Resonance (EPR) or Electron Spin Resonance (ESR) spectroscopy is a powerful analytical technique that plays a vital role in understanding the structure and properties of paramagnetic materials. Several companies are offering EPR spectroscopy solutions in the UK. This blog post will introduce some of these EPR brands, including their features, and pricing options.

Bruker Corporation

Bruker is a globally recognized brand known for its high sensitivity, versatility, and advanced software features, offering a full range of EPR spectrometers suitable for a variety of research applications. The price of a Bruker EPR system depends on the model and configuration.

CIQTEK

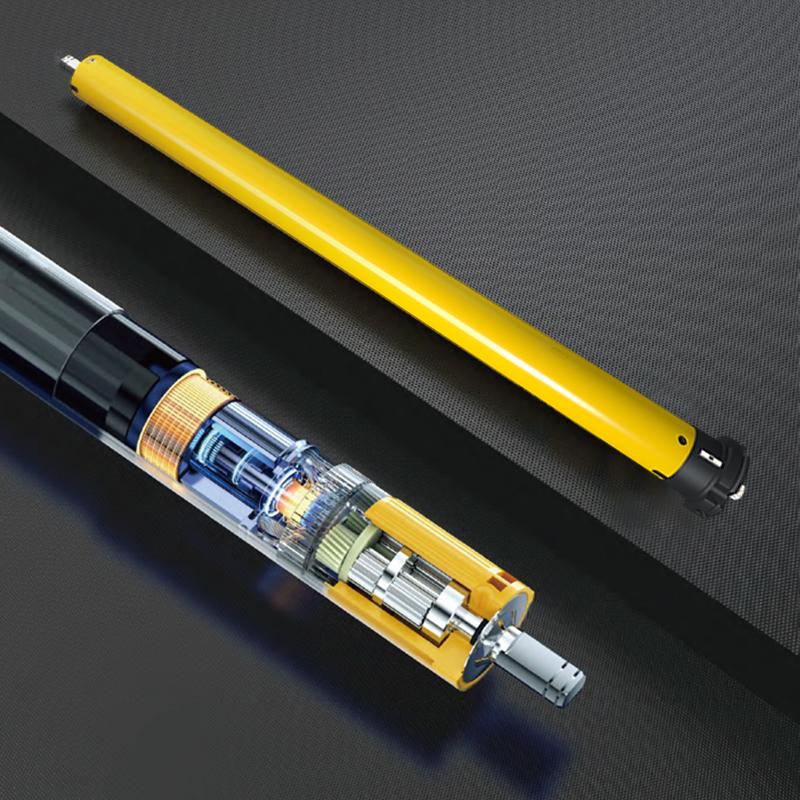

CIQTEK is a leading global manufacturer of EPR spectrometers and related accessories. Their EPR equipment is designed to provide the highest performance at a very competitive price and is an excellent choice for researchers in the UK. Website: https://www.ciqtekglobal.com/

Here are some advantages of CIQTEK EPR spectroscopy:

a. Cost-effective solutions: While EPR spectroscopy equipment is often expensive, CIQTEK strives to offer competitive pricing without compromising quality. They offer different pricing options so research groups and organizations with different budgets can use their instruments. In addition, they are committed to customer satisfaction to ensure that users get value for their investment.

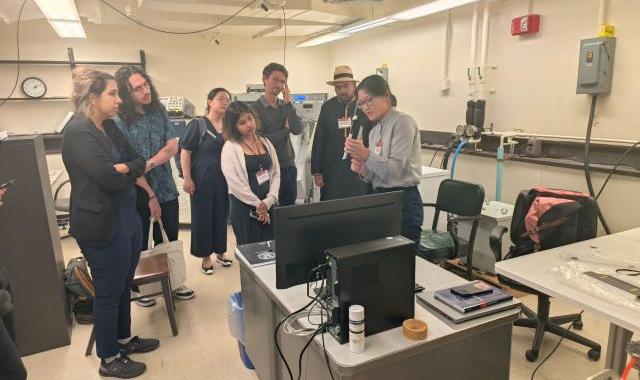

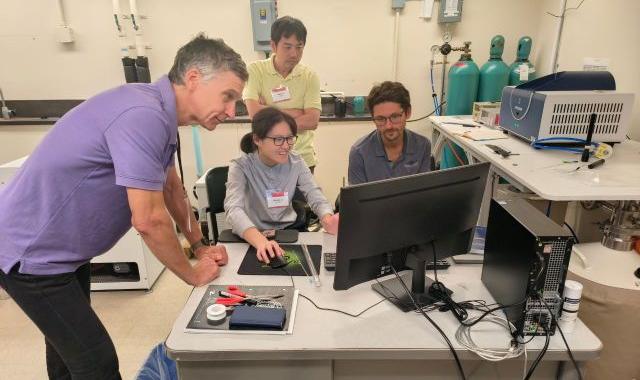

b. Customizability: CIQTEK offers flexible EPR instrument configurations that allow researchers to customize EPR setups for specific experimental requirements. These include variable temperature control, multi-frequency capability, advanced spectroscopic techniques such as ELDOR and HYSCORE, and compatibility with a wide range of sample types (liquids, solids, and biomaterials.)

c. User-Friendly Interface: CIQTEK's instruments come with an intuitive software interface that is easy to use and suitable for researchers of all experience levels.

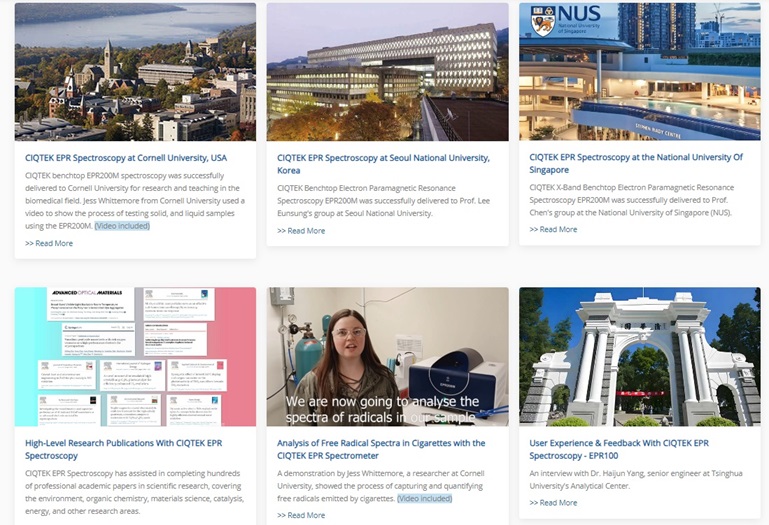

d. Excellent Customer Support: CIQTEK emphasizes customer satisfaction and provides excellent post-sales support, including training resources and technical support. Click to read CIQTEK global EPR customer stories and publications.

JEOL

JEOL is a well-known brand in the field of EPR spectroscopy, offering reliable, high-performance instruments. JEOL EPR instruments offer advanced features such as fast scanning capabilities, high signal-to-noise ratios, and user-friendly interfaces.

Oxford Instruments

Oxford Instruments is a leading supplier of scientific equipment including EPR spectrometers. They offer rugged and customizable EPR systems to suit a wide range of research needs.

In the field of electron paramagnetic resonance spectroscopy, researchers in the UK have access to a wide range of reliable, high-performance instruments from a variety of brands. From Bruker, JEOL, and Oxford Instruments, to the most competitive CIQTEK, there are options to suit a range of budgets and research needs. When considering a purchase, it is important to evaluate each brand's unique features, pricing, and benefits to make an informed decision.