Precautions for Using North Edge Outdoor Watch on Mountain Climbs

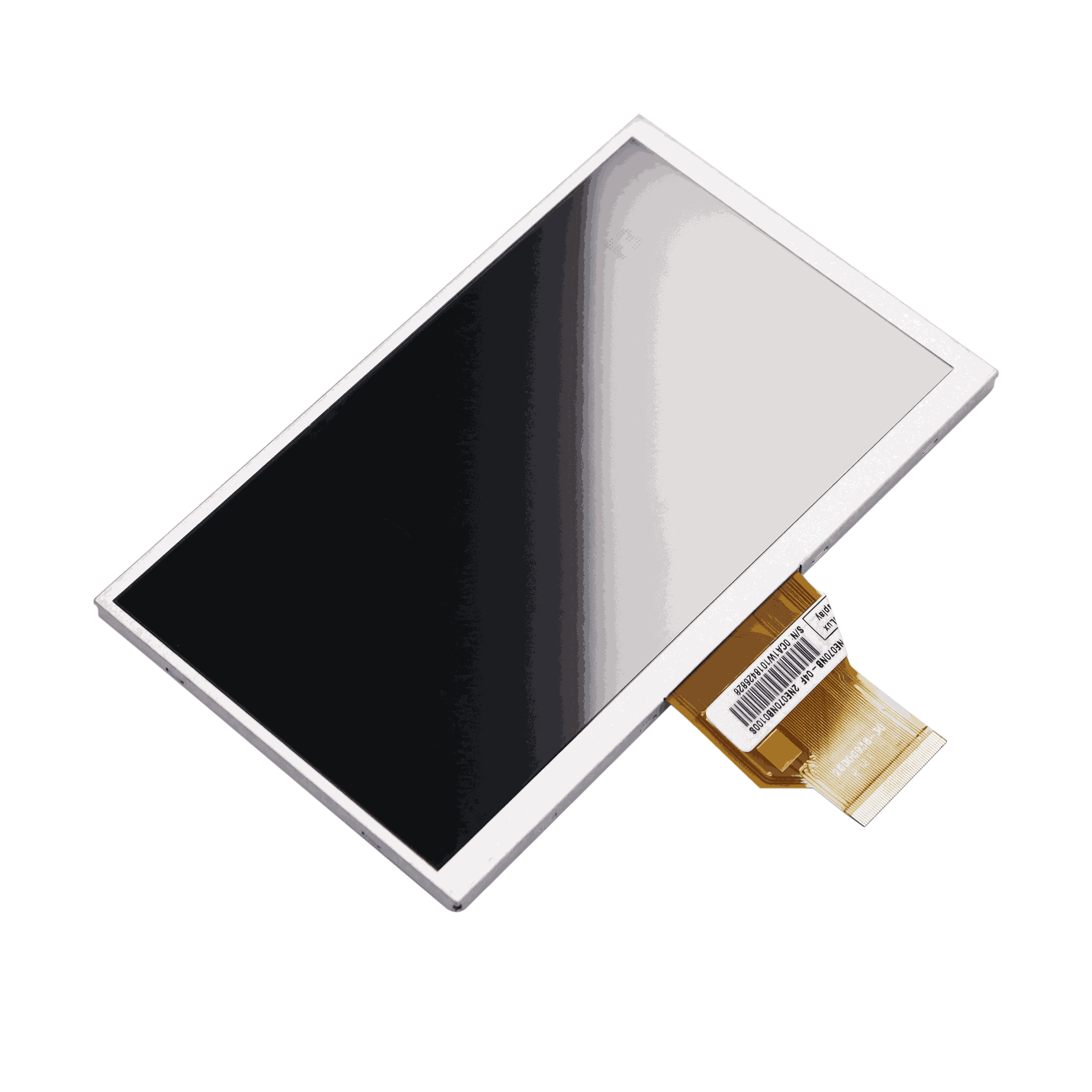

When it comes to climbing mountains, an outdoor watch can be an invaluable tool. And when it comes to reliable outdoor watches, North Edge watch is a brand that stands out. It not only helps us keep track of time but also provides various useful functions like altitude measurement, barometer readings, and compass directions, which are essential for a safe and enjoyable mountain climbing experience.

1. Before climbing, make sure the North Edge outdoor watch is fully charged or has sufficient battery life. This is crucial as you don't want your watch to run out of power in the middle of your adventure, especially when you rely on its functions for navigation and monitoring.

2. Familiarize yourself with the functions of the watch, such as the altimeter, barometer, and compass. North Edge watches are equipped with these advanced features, and knowing how to use them correctly will enhance your climbing experience and ensure accurate readings.

3. Wear the watch firmly to prevent it from falling off during the climb. A secure fit is essential, especially in rugged terrains where sudden movements or impacts can cause the watch to loosen or fall. North Edge watches often come with adjustable straps or bracelets that allow you to find the perfect fit for your wrist.

4. Protect the watch from impacts and scratches. Avoid knocking it against hard objects. The durability of North Edge watches is designed to withstand outdoor conditions, but excessive impacts can still damage the watch.

5. In bad weather conditions, such as heavy rain or snow, take proper measures to protect the watch from water damage.

6. Regularly check the accuracy of the watch's functions, especially the altimeter and compass. North Edge watches are known for their accuracy, but regular checks are necessary to ensure that you are getting reliable readings.

7. When not in use, store the watch in a safe and dry place to prevent damage. A proper storage environment will extend the lifespan of your North Edge watch.

In conclusion, following these precautions when using a North Edge outdoor watch during mountain climbing can enhance our safety and enjoyment of the outdoors.